In the dynamic world of electrical conductivity, aluminum, and copper stand as two of the paramount players. These metals, each with its unique set of characteristics, have illuminated our homes, powered our industries, and steered innovations for decades. Yet, marrying these two giants in the realm of electrical engineering is no ordinary feat. As we delve into the nuanced methods of transitioning from aluminum to copper, we’ll uncover the intricacies, challenges, and undeniable potential that lies in this union. Join us on this electrifying exploration of metalwork mastery.

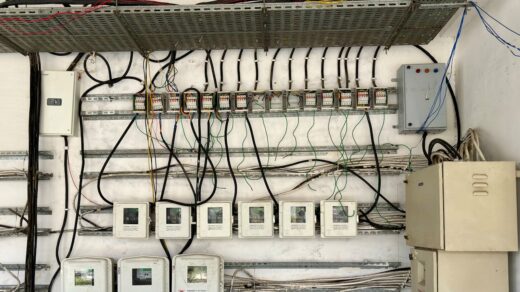

Techniques in Connecting Aluminum to Copper

The dominant procedure for conjoining aluminum to copper revolves around pigtails and sanctioned connectors. One should intertwine a diminutive strand of copper with the pre-existing aluminum strand, subsequently employing a bi-rated connector for attachment. It’s imperative that this connector complies with Canadian standards and is distinctly labeled for aluminum-to-copper connections. Additionally, the device’s endpoint should be linked with the copper wire.

For the conservation of aluminum’s conductivity during this intertwining process, an antioxidant cream application is indispensable.

There exists an alternative method that entails a distinct purple COPALUM connector. This approach demands specific equipment and the expertise of a certified electrician due to its intricate nature. Given the substantial dimensions of COPALUM connectors, an enlargement of the electrical box becomes a prerequisite, often escalating the overall expenditure.

Reasons to Consider Copper over Aluminum

Aluminum’s role in domestic wiring is both noteworthy and debatable. Contrary to misconceptions, aluminum wiring, when coupled with the right methodologies and components, stands safe. Its introduction during the mid-20th century offered a budget-friendly alternative to the then-prevalent copper wiring. Interestingly, copper’s superior conductivity was evident from inception.

Concerns with Aluminum Wiring

To compensate for the differential conductivity, more voluminous aluminum wires were utilized to match copper’s efficacy. However, the identical installation techniques for both metals led to certain challenges with aluminum, such as inconsistent illumination, elevated cover plate temperatures, and insulative deterioration. These anomalies underlined the necessity for refining aluminum connections.

Expert Assistance & Recommendations

For residents in the Ottawa vicinity pondering over the aluminum to copper wiring transitions, consultation is paramount. Embarking on such ventures without professional oversight might be perilous. For comprehensive insights and guidance on aluminum wiring nuances, consider engaging with expert services like Mike Fuller Electric.

Comparison Table: Aluminum vs. Copper Wiring

| Features | Aluminum | Copper |

|---|---|---|

| Conductivity | Good | Superior |

| Historical Use | Introduced in mid-1960s | Prevalent before 1960s |

| Common Issues | Inconsistent illumination | Rare |

| Overheating | ||

| Installation Adjustments | Requires larger wire | Standardized |

| Connector for Transition | COPALUM (Larger) | Bi-rated |

Video Guide

If you still have questions, we suggest you watch the video we have prepared for you. Enjoy watching it!

Conclusion

In conclusion, the transition from aluminum to copper in electrical systems is not just a mere choice but a reflection of understanding conductivity, safety, and efficiency. While aluminum offered a cost-effective solution in its time, the evident benefits of copper and the challenges posed by aluminum wiring necessitate thoughtful consideration. Engaging with professional advice and ensuring compliance with recognized standards becomes paramount. As the realm of electrical installations continues to evolve, staying informed and prioritizing safety will always be the guiding principles.