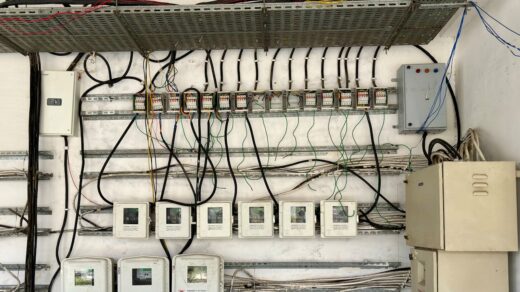

“Somebody do something! Somebody call somebody!” – phrases from the movie “Seven” popped into my brain when I saw this picture.

There was a metal nut hanging from the “sharp” ends of the input breaker. I broke into a sweat as I imagined what could happen at any moment. And how long had that nut been there, had it been there since the last round, or had it come loose a second ago, while the cabinet door was being opened?

That said, the production line in question was running on all fumes. The line is such that it is operated by more than 10 people, and there are several similar bushings with a busbar connection. Since a strong vibration in this place – common, this metal nut, unscrewed from the input coupling, at any time could slip down, move a couple of millimeters, and then … What then – talk in this article.

Short circuit conditions

To get a fuller sense of the problem we’re going to talk about, read my recent article – what is the short circuit current – its causes, varieties, measurement, etc.

What do we have? The power line in this case has this structure.

Voltage source – KTP (complete transformer substation) with a transformer 10/0,4 kV, capacity 1000 kVA:

As part of the KTP – automatic circuit breaker drawout type AVM-20, made in the Brezhnev era, with unknown settings for overcurrent (overload and short-circuit).

From the ABM-20 circuit breaker, voltage is supplied to the ShRA-73 busbar trunking with aluminum busbars. Rated current is 630 A. Length – about 70 m.

Feeding single-core flexible cables of KG type with 95 mm² cross-section are connected to the busbar. The length of this section – 15 m.

The terminals are aluminum-copper, we wrap the crimping point with white duct tape. Why not with white heat shrink? Because white duct tape is always at hand, but white heat shrink wrap with a hair dryer is not. Why white tape?

Through the cable sleeves, the wires enter the power cabinet to the terminals of the ABB OT630E30 circuit breaker with a rated current of 630 A.

From the given data we can judge that the short circuit current at the point of supposed short circuit should be enormous – more than 10 kiloamperes. And the consequences – fairy-tale!

What could be the consequences of the short circuit?

Electricians are people who always think of the worst. Of course, that doesn’t mean they are pessimists. They think about the worst-case scenario – about the maximum allowable current in the circuit (from that choose a circuit breaker), or that most people, pulling the plug out of the socket, do not think about the reliability of fixing the socket in the wall (so you need to additionally fix the socket with screws, not hoping for the usual “legs”)

What could it be? This is not the kind of short circuit that would occur with a short in the outlet! There could have been far worse consequences in this incident! Here’s what came to mind when I calmed down a bit:

- The nut would simply burn out as a result of the nut short-circuit, the protection might not work, and no one would notice anything until the next bypass. This is the easiest outcome.

- The circuit breaker on the switchgear supplying the line could have been tripped. Short-circuit tripping is always, if not an accident, the limit modes and overloads for all elements of the system, especially with such currents. In addition, a sudden abnormal shutdown of the line leads to material and time losses. And nerve cells, they say, do not recover at all.

- If the circuit breaker failed to trip, the fault could have created an arc, which is not easy to stop. An arc is actually a powerful open flame that easily leads to a fire. The arc current is less than the short-circuit current, and the breaker would be out of action. It is good that the cabinet is closed and sealed, the air cooling has a closed circuit, with cooling from a cold water circuit.

- Short circuit and arc is a powerful electromagnetic interference, which very negatively affects even the power circuits, not to mention the control and communication circuits. In the same cabinet there are two frequency converters that control 1.5 kW synchronous motors with resolvers, and a 75 kW DC motor driver. Control is via ProfiBus, which also goes to other frequency converters and controllers. All of this could have fun and with special effects, bringing the equipment into prolonged downtime.