In a previous article about the consequences of a short circuit, I promised to continue the topic and tell about the installation of a circuit breaker IEK VA88-37 instead of input breaker ABB OT630E30.

Promised – I carry out. But along the way I decided to deal with the parameters of circuit breakers (they are also called “circuit breakers in the molded case”, and compare them with the “normal” circuit breakers.

Usually, I usually write my articles according to the rule: first theory, then – practice. This time I will break the rule, and first I will tell why I installed a circuit breaker, then – how, and only then we will go over the theory.

Why was it necessary to replace the circuit breaker with a circuit breaker?

For those who do not know and do not want to go to the link at the beginning of the article: it so happened that two events coincided – 1) a nut fell on the “sharp” ends of the breaker and for little did not arrange a big boom, and 2) input breaker began to crunch and wedge when switching. It was decided to send a procurer to the “Electrician” for a circuit breaker before it is too late.

Why a circuit breaker IEK with a rated current of 315 A instead of the switch ABB with a rated current of 630 A, you ask? It’s not the brand, but the fact that the price IEK – several times lower, and buy it in Taganrog in half an hour. The AVB OT630E30 switch is on this line in two places and in spite of the brand, it has already been broken 2 times. Apparently, the reason is the silumin cams that transmit the motion from the rod – they break and the switch becomes the cause of a long downtime. We didn’t wait for the third time.

Switch

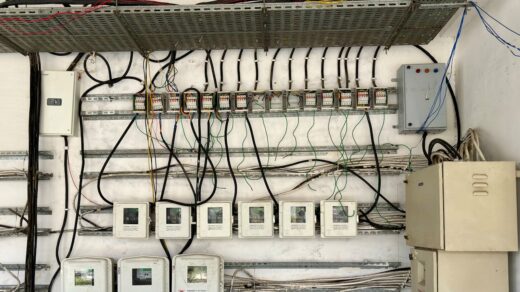

The ABB circuit breaker has a rated current of 630A. The third pole in the photo is notable because its gray cover has fallen off and there is a metal nut hanging from the top terminal.

The plus side of the circuit breaker is that it provides additional overcurrent protection, which the circuit breaker does not have. It never opens at the rated current, and the frequency of switching off is about once a day. Therefore, arc suppression and wear resistance are out of the question. The only disadvantage of such replacement – you need a slight modification of the design, because the mounting of the circuit breaker and breaker are different.

Looking ahead, I will also say that I installed a remote handle on the door and a mechanism for remote shutdown (steel rod) on the machine. I will also tell you about this in the article.

Can I do such modifications on the industrial equipment? It is possible, and even necessary. Moreover, it has to be done regularly. Of course, no one can do modernization on their own – before that there is a process of approval and preparation. I wrote about how it happens at our plant in the article How the energy service at the plant is organized.

Installing the circuit breaker IEK VA88-37

In order to install the circuit breaker I had to mark a metal panel and then cut 4 threads for pins (screws) M5, which are used to install the circuit breaker. The studs and other fasteners are included.

Then the lead-in wires were screwed (more precisely, single-core cables KG-95). Stock cables (about 50 cm) are located on the roof of the cabinet.

For connoisseurs of beauty and colored heat shrink: why this was done, explained in the first part (link at the beginning of the article). There is even a link to an article about white duct tape.

Note that the terminals with cable lugs are recessed deep in the body of the circuit breaker, and this is much safer than in the ABB circuit breaker.

In addition, remembering the previous troubles, it was obligatory to install the baffles between the phases, which were also included.

On the lower terminals screwed bars.

The circuit breaker is installed.

On one side of the circuit breaker with a rated current In = 315 A, connected to the supply wires cross section of 95 mm2, which have a long-term current rating of 255 A when laid together open (in the metal cable tray). On the other side – a technological line with installed (maximum theoretical) power of 140 kVA (current on each phase – about 200 A).

Mounting the remote handle on the circuit breaker IEK 88-37

On / off this circuit breaker is made about once a day. Not often. But without a handle on the door to operate such a circuit breaker is uncomfortable and unsafe – because you need to open the door of the cabinet, and it should do only qualified electrical personnel. That’s why we installed a handle on the cabinet door with a remote control mechanism. This mechanism is a special attachment to the machine with a steel rod, and is purchased separately. The official name – “Manual rotary actuator PRP1-37”.

I will tell you step by step about the installation process of the accessory “PRP1”, which is essentially an intermediary between the automatic switch and the person who turns the handle on the door of the cabinet.