In the realm of electrical wiring, the transition from aluminum to copper conductors has been a subject of continuous discourse and inventive exploration. While it was initially celebrated as an economical substitute for copper, it has confronted a range of challenges over time, including apprehensions regarding safety and dependability. In response to these challenges, the notion of utilizing aluminum to copper wire pigtails has surfaced as a revolutionary remedy, effectively bridging the gap between these two materials and augmenting the performance and safety of electrical systems.

Aluminum Wiring in Homes: A Comprehensive Guide

Aluminum wiring pigtails play a crucial role in enhancing the protection of residences against the hazards associated with aluminum terminations. Let’s delve into the fundamental aspects:

- Prioritizing Safety: Pigtails effectively address the potential issue of overheating, which can arise from weak connections or the use of inappropriate electrical devices;

- Widespread Usage: A substantial number of households in Ottawa and across Canada continue to rely on it, either exclusively or in combination with copper wiring;

- Expert Recommendation: When dealing with aluminum wiring, it is highly advisable to always consider the inclusion of pigtails as a means to fortify the security and reliability of electrical connections.

Why Was It Popular?

Aluminum wiring was the go-to choice for many Canadian homes between the mid-1960s and the late 1970s. What contributed to its fame?

- Cost-Effectiveness: It was a more affordable alternative to copper during this period;

- Conductivity: Despite being economical, aluminum didn’t compromise on quality and was an effective conductor of electricity;

- Challenges: On the downside, aluminum is softer than copper, making it prone to nicks. This softness can cause misshaping over time, potentially disconnecting wires from terminals;

- Insight: Loose connections, combined with electrical arcing, can sometimes result in burnt plugs and wire connectors, so vigilance is key when maintaining such systems.

Debunking Myths Surrounding Aluminum Wiring

Despite its widespread usage in the past, there are misconceptions about aluminum wiring that need to be clarified:

- Recall Rumors: Contrary to popular belief, it was never “recalled.” Such notions might stem from isolated incidents or misconceptions;

- Safety and Approval: It hasn’t been banned or deemed impermissible for homes. When installed correctly, using the right materials and techniques, it is perfectly safe;

- Cost-Effective Solution: While some homeowners might contemplate rewiring their homes with copper, sticking with aluminum remains a financially savvy alternative, as long as proper installation practices are adhered to.

Elevating Home Safety: Transitioning from Aluminum to Copper Wiring

In the vast world of electrical systems, when faced with the challenges posed by aluminum wiring, adopting an aluminum-to-copper wire pigtail connection stands out as a practical and cost-savvy approach. Expert electricians often recommend this method as a foolproof strategy, not only offering homeowners significant time efficiency but also ensuring the longevity of their investments and paramountly, their safety.

Diving Deep: Unraveling the Aluminum to Copper Wire Pigtail Technique

The art of pigtailing aluminum to copper is a meticulous process, demanding the fusion of these two different metals using connectors that are especially designed to cater to both. To add an extra layer of security, the application of an antioxidant compound during this connection is a must to combat the insidious threat of corrosion – a formidable foe that can degrade connections, culminating in hazardous outcomes like overheating or sparking, and endangering nearby flammable substances.

Decoding the Aluminum to Copper Wire Pigtail Procedure:

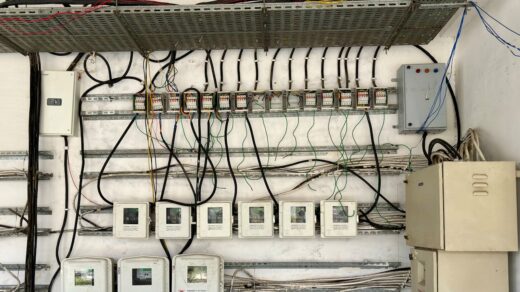

Diagnostic Review: The journey begins with an expert electrician, proficient in tackling vintage aluminum wire setups, embarking on a detailed scrutiny of the entire electrical setup. This pivotal phase lays the groundwork to spot any lurking issues and gauge the overall health and safety of the system.

- Art of Splicing: Here, the electrician masterfully intertwines the aluminum and copper wires, relying on special connectors crafted exclusively for this merger. The dual-rating of these connectors is a testament to their adaptability with both wire variants;

- Guard Against Decay: As a preemptive strike against potential decay, the antioxidant compound is diligently applied. This not only cements the bond between the wires but also wards off corrosion, ensuring the longevity of the connection;

- Handling with Care: Aluminum, being softer than copper, necessitates delicate handling. Ensuring the aluminum wire remains untainted by scratches or hairline fractures is paramount, as these seemingly minute flaws can escalate to grave safety hazards;

- Space Optimization: In scenarios where the electrical box is cramped for space, integrating a mounted box extension ring can be the saving grace, ensuring all connections snugly fit in;

- Insist on Expertise: It’s non-negotiable – entrusting the task of pigtailing aluminum wiring to a seasoned electrician is a must. Venturing into this territory without the requisite knowledge can not only amplify existing problems but also jeopardize safety;

- A Surgical Approach: Dispelling the myth that homes with aluminum wiring beckon for a total overhaul, it’s often the case that a strategic repair is all that’s needed. Under the watchful eye of a Licensed Electrical Contractor, this surgical repair not only eradicates potential dangers but also aligns perfectly with the benchmarks set by the Electrical Safety Authority.

Understanding Aluminum Wiring: Risks, Insurance, and Regulations

Aluminum wiring, once a popular choice for residential construction, has in recent years come under scrutiny due to potential fire hazards. Delving deeper into the research and regulatory landscape can provide homeowners and potential buyers with invaluable insights on the subject.

Unveiling the Hazards of Aluminum Wiring:

- Statistical Insight: Research spearheaded by the Consumer Product Safety Commission brought to light the serious fire threats posed by aluminum wiring. A striking revelation from this research is that homes equipped with aluminum wiring are at an alarming 55-fold higher risk of encountering “Fire Hazard Conditions” than their copper-wired counterparts;

- Potential Risks: The vulnerability stems from certain characteristics of aluminum wiring. Minute imperfections like scratches, nicks, or even hairline fractures can precipitate overheating, culminating in a significant fire hazard.

Navigating Insurance Hurdles with Aluminum Wiring:

For homeowners in certain regions, such as Ontario, insurance complications can arise if their homes have aluminum wiring. Here are some crucial points to keep in mind:

- Securing a Certificate of Inspection: A pivotal step in getting insurance coverage is obtaining a Certificate of Inspection. This certification, dispensed by the Electrical Safety Authority (ESA), authenticates the safe status of the home’s aluminum wiring;

- Meticulous Wiring Practices: Ensuring safety isn’t merely about having the right materials but also about implementing meticulous installation and maintenance practices. Any endeavor involving aluminum wiring must strictly avoid compromising the wire’s integrity, which can otherwise pave the way for dangers;

- Involving Expertise: The intricacies of dealing with aluminum wiring necessitate expertise. Entrusting a professional electrician is paramount. Their profound knowledge ensures that connections are not just effective but also safe;

- Regulatory Affirmation: Notably, the Ontario Electrical Safety Code hasn’t blacklisted aluminum wiring for residential setups. It continues to be permissible, provided it aligns with the stipulated safety guidelines and protocols.

Recommendations for Homeowners:

- Routine Inspections: Regularly engage with a professional electrician to inspect and maintain the system;

- Stay Updated: Keeping abreast with local regulations and insurance prerequisites can save homeowners from potential future complications;

- Consider Upgrades: If feasible, contemplate transitioning to copper or employing mitigation methods to enhance safety.

By arming themselves with the right knowledge and taking proactive measures, homeowners can navigate the complexities associated with it with confidence and safety in mind.

Conclusion

To sum up, the technique of connecting aluminum to copper wires through pigtail splicing emerges as a dependable remedy for homeowners grappling with the intricacies of it. When proficiently undertaken by a seasoned electrician, it guarantees not only safety but also adherence to regulatory standards, offering a profound sense of security. It is crucial to underscore that when navigating the complexities of electrical systems, prioritizing safety above all else is imperative, and the invaluable counsel of a professional remains an indispensable asset in this endeavor.