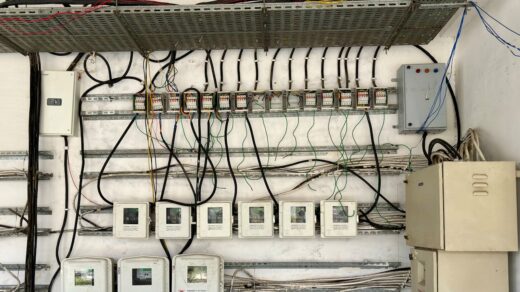

Electrical cables play a pivotal role in today’s world, channeling the power we need across our homes, workplaces, and factories. But what exactly are these cables composed of? Dive into this detailed overview as we unravel the elements that make up these crucial connectors, from their conductive heart to their safeguarding outer layers. Grasping the makeup of electrical cables isn’t just intriguing but also vital for maintaining a secure and high-performing electrical network.

Conductive Core

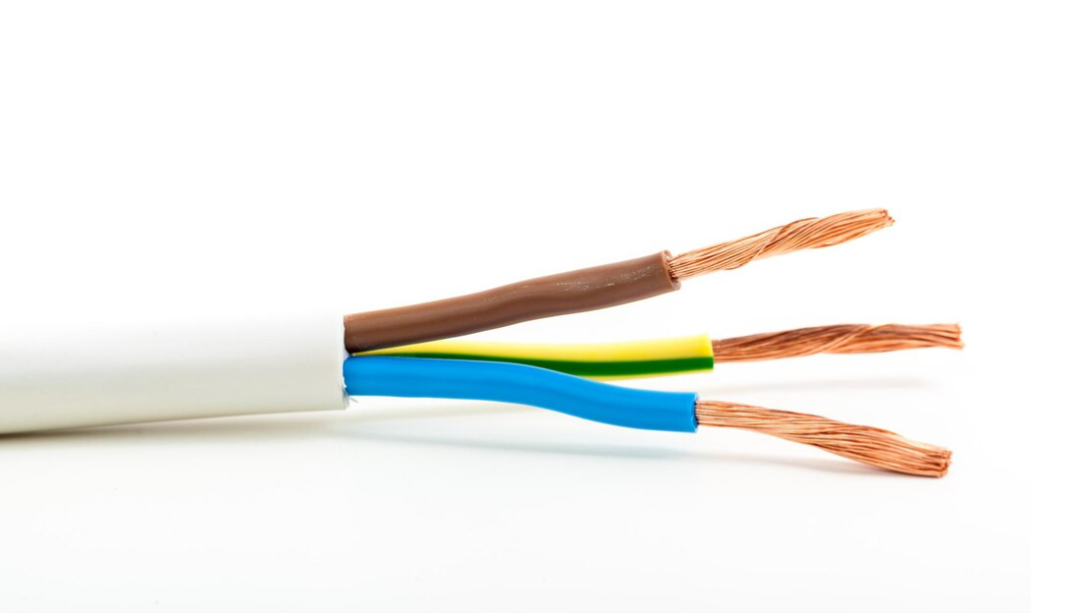

Deep within every electric cable is its vital conductive heart, typically fashioned from either copper or aluminum. These metals are distinguished by their impressive electrical transmission properties, making them top picks for the unhindered flow of electric current. The primary materials selected for this purpose are:

- Copper: Esteemed for its superior electric conduction capabilities and resilience to corrosion, copper sits atop the list of preferred conductor materials. Its adeptness at transmitting electricity makes it a prime choice for diverse electrical tasks;

- Aluminum: Often chosen for high-voltage power routes, aluminum conductors have gained traction. While its conductivity might be a tad below copper, its lightweight nature and cost-effectiveness earmark it as an excellent option for expansive power conveyance.

Insulation Materials

Enveloping the conductive core lies a protective layer of insulation material, a crucial element tasked with shielding the wire and thwarting electrical leakage. The selection of insulation materials hinges on the wire’s designated purpose and the prevailing environmental conditions.

A diverse array of insulation materials is at the disposal of electrical engineers and designers, each meticulously chosen to serve a distinct purpose:

- Polyvinyl Chloride (PVC): PVC insulation, renowned for its durability and resilience, exhibits exceptional resistance to moisture and abrasion. This makes it a top choice for safeguarding indoor electrical wiring, where longevity and robust protection are paramount;

- Cross-Linked Polyethylene (XLPE): XLPE insulation steps up to the plate when exceptional thermal and chemical resistance are prerequisites. It’s particularly well-suited for underground wiring and applications demanding resistance to high temperatures and corrosive substances;

- Thermoplastic High-Heat-Resistant Nylon (THHN): THHN insulation boasts a reputation for its prowess in conduit wiring scenarios. It earns its stripes by providing remarkable heat resistance, ensuring electrical integrity even in demanding environments;

- Rubber: Rubber insulation, known for its flexibility and remarkable tolerance for extreme temperatures, becomes the go-to choice for portable cords and rugged industrial settings. Its ability to withstand harsh conditions while remaining pliable makes it an indispensable option;

- Silicone: When the temperature gauge rises, silicone insulation steps in with its exceptional high-temperature resistance and flexibility. This makes it an excellent candidate for appliances and electronic devices that operate in thermally demanding conditions.

In essence, the selection of the appropriate insulation material goes far beyond mere protection; it’s a tailored approach to ensuring electrical integrity and longevity under specific circumstances.

Protective Sheath

The outermost layer of an electrical wire is the protective sheath, which shields the wire from physical damage, moisture, and environmental factors. Common sheath materials include PVC, thermoplastic, and rubber.

The type of sheath used depends on the wire’s intended application. For example, outdoor wiring requires a sheath that can withstand exposure to the elements, while indoor wiring may use a simpler PVC sheath.

In some cases, an additional outer layer, called the jacket, is applied to electrical wires. The jacket provides extra protection against environmental factors such as moisture, chemicals, and abrasion. Jacket materials can include PVC, thermoplastic elastomers (TPE), or even metal in armored cables.

Types of Electrical Wire Materials

Electrical wires, like tools in a craftsman’s toolbox, come in an assortment of types, each meticulously designed to excel in particular applications. These wire variations, often categorized by the materials they are composed of, allow electrical engineers and designers to fine-tune their choices for optimum performance. Here, we delve into some of the common types, each defined by the materials used in its construction:

- Copper Wiring: A stalwart of the electrical world, copper wiring finds its way into numerous residential and commercial applications. Revered for its exceptional electrical conductivity, ductility, and corrosion resistance, copper wiring stands as the go-to choice for a wide spectrum of wiring needs. Whether it’s powering your household appliances or lighting up an office building, copper wiring consistently delivers the reliability and performance demanded by modern electrical systems;

- Aluminum Wiring: In the realm of high-voltage transmission lines and industrial settings, aluminum wiring assumes its role with distinction. While being more cost-effective than its copper counterpart, aluminum exhibits commendable electrical conductivity. However, it’s worth noting that aluminum wiring may necessitate special connectors and maintenance to mitigate certain challenges, such as issues related to oxidation and thermal expansion;

- Copper-Clad Aluminum (CCA) Wiring: Copper-clad aluminum (CCA) wiring emerges as a harmonious amalgamation of copper’s conductivity and aluminum’s cost-effectiveness. This hybrid material is employed in select applications, offering a compromise between the two prominent metals. While CCA wiring provides a balance between performance and affordability, it may have certain limitations, particularly concerning ampacity, which needs careful consideration during installation.

Specialized Wire Types

| Specialized Wire Type | Description |

|---|---|

| Fiber Optic Cables | Transmit data as light pulses for high-speed communication, revolutionizing the internet, telephony, and data centers. |

| Thermocouple Wires | Precisely measure temperature by generating voltage in response to changes, essential in manufacturing and aerospace. |

| Shielded Cables | Protect electronics from EMI with shielding layers, common in medical, aerospace, and high-speed data transmission. |

| Coaxial Cables | Ensure precise signal transmission with central conductors and shielding, ideal for TV, internet, and radio communication. |

| High-Temperature Wires | Endure extreme heat using materials like silicone rubber or fiberglass insulation, crucial in industrial and aerospace settings. |

Beyond the fundamental components discussed earlier, the world of electrical wires encompasses a diverse array of specialized types, each meticulously engineered to address specific challenges and applications. Let’s explore some of these specialized wire types in greater detail:

Fiber Optic Cables

Fiber optic cables are the backbone of our modern telecommunications infrastructure. Instead of traditional copper conductors, these cables employ ultra-thin strands of glass or plastic to transmit data as pulses of light. This technology allows for incredibly high-speed data transmission over long distances, making it indispensable for internet connectivity, telephone networks, and data centers. Fiber optics have revolutionized the way we communicate, providing the bandwidth needed for streaming, video conferencing, and more.

Thermocouple Wires

In industries like manufacturing, research, and aerospace, precise temperature measurement is essential. Thermocouple wires are designed for this purpose. They consist of two dissimilar metal wires joined at one end, forming what’s known as a thermocouple junction. When exposed to varying temperatures, this junction generates a voltage proportional to the temperature difference. This voltage is then used to accurately measure and control temperature in applications ranging from ovens and furnaces to scientific experiments.

Shielded Cables

Electromagnetic interference (EMI) can wreak havoc on sensitive electronic equipment. To combat this, specialized electrical wires feature a shielding layer made of materials like aluminum or copper foil. This shield acts as a protective barrier, deflecting and absorbing unwanted electromagnetic radiation. Shielded cables are commonly used in environments where EMI is a concern, such as medical equipment, aerospace systems, and high-speed data transmission lines. They ensure that electronic signals remain clean and interference-free, preserving the integrity of critical operations.

Coaxial Cables

Coaxial cables are a staple in applications requiring precise signal transmission. They consist of a central conductor surrounded by an insulating layer, a metallic shield, and an outer insulating layer. This construction minimizes signal loss and interference, making coaxial cables ideal for transmitting high-frequency signals, including cable television, internet connections, and radio communication.

High-Temperature Wires

Some industrial processes and aerospace applications expose electrical wires to extreme temperatures. High-temperature wires are specially designed to endure these harsh conditions. They often feature insulation materials like silicone rubber or fiberglass that can withstand temperatures well above the capabilities of standard wires. These wires are crucial in industries where maintaining electrical connectivity under extreme heat is imperative.

Conclusion

Understanding what electrical wires are made of is essential for homeowners, electricians, and anyone working with electrical systems. The materials used in electrical wires impact their performance, safety, and longevity. Whether you’re installing new wiring or assessing an existing system, knowledge of wire composition is key to ensuring a reliable and efficient electrical system. By knowing the materials that make up electrical wires, you can make informed decisions that contribute to the safety and functionality of your electrical infrastructure.