When it comes to the safety and efficiency of your home or office electrical system, understanding the lifespan of your electrical wires is crucial. An outdated or worn-out wiring system can lead to electrical malfunctions, increased energy bills, or even fires. This article sheds light on how long electrical wires last, the factors that influence their lifespan, and when it’s time to consider a replacement.

Table of Contents

- Factors Influencing the Lifespan of Electrical Wires;

- Common Types of Electrical Wires and Their Lifespans;

- 3.1 Copper Wire;

- 3.2 Aluminum Wire;

- 3.3 Fiber Optic Cable;

- 3.4 Coaxial Cable;

- Warning Signs That It’s Time to Replace Your Wiring;

- Tips for Extending the Lifespan of Electrical Wires;

- Conclusion.

Factors Influencing the Lifespan of Electrical Wires

The durability and longevity of electrical wires are pivotal concerns for homeowners, electricians, and industrial establishments alike. A deeper understanding of what affects the lifespan of these wires can not only ensure safety but also lead to cost savings in the long run. The longevity of electrical wires is not solely a matter of time; it’s intertwined with various factors that can either extend or reduce their effective lifespan. Here’s a more detailed exploration of these influential factors:

- Material Composition: The inherent qualities of the material from which a wire is made play a significant role in its lifespan. Different materials possess unique electrical, thermal, and mechanical properties, which in turn affect their durability. Copper, for instance, is renowned for its excellent conductivity and resistance to corrosion, allowing it to often outlast aluminum wiring. Aluminum, while being lighter and more cost-effective, can be prone to oxidation, which might compromise its longevity compared to copper;

- Operational Demand (Usage): Just as a frequently used machine shows wear over time, electrical wires that are subjected to continual or heavy loads can degrade more rapidly. Intermittent use or moderate loads can potentially increase the lifespan of wires, whereas constant exposure to high currents can expedite insulation breakdown or increase the risk of other electrical issues;

- Environmental Conditions: The surrounding environment in which the wires operate can be a deciding factor in their longevity. For example, a humid environment can accelerate the oxidation process in some metals, leading to reduced efficiency and potential safety hazards. Similarly, wires exposed to corrosive chemicals or saline conditions may see a more rapid decline in their performance. On the other hand, wires operating in stable, dry, and temperate environments tend to have prolonged lifespans;

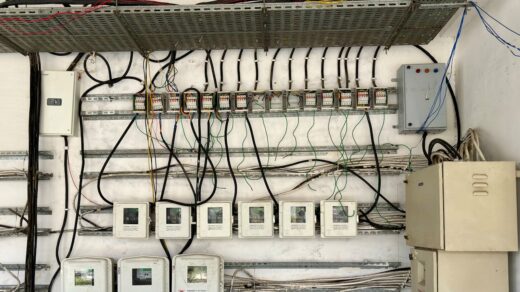

- Quality of Installation: The skill and expertise with which wires are installed can significantly influence their longevity. Proper installation involves ensuring that wires are suitably insulated, not overly bent or stressed, and are kept away from potential hazards. Moreover, good practices, such as not overloading circuits and using the right wire gauge for specific applications, can further ensure that wires serve their intended purpose for years without faltering.

Common Types of Electrical Wires and Their Lifespans

Copper Wire

- Lifespan: Approximately 40-70 years

Copper is often the go-to choice in the realm of electrical wiring, largely attributed to its stellar conductivity and remarkable resilience. Its inherent properties make it adept at efficiently conducting electricity while resisting wear and tear. When maintained appropriately, with regular checks and avoiding overloads, copper wiring stands the test of time, serving reliably for many decades.

Aluminum Wire

- Lifespan: Roughly 30-50 years

Aluminum provides a more economical alternative to copper, both in terms of weight and cost. Its lightweight nature makes it a favorite for large-scale installations where weight considerations are crucial. However, it’s worth noting that aluminum is susceptible to oxidation, especially when exposed to moisture. This oxidation can result in decreased efficiency and potential safety concerns. As a result, while aluminum does offer substantial benefits, its longevity might fall a bit short compared to the enduring nature of copper.

Fiber Optic Cable

- Lifespan: Typically 20-40 years

Fiber optic cables represent the cutting-edge frontier of data transmission technology. Diverging from conventional electrical conduits, these cables rely on light to transmit data, resulting in exceptionally high speeds and minimal signal interference. Given their unique mode of operation, they remain largely immune to many electrical disturbances. Nevertheless, they aren’t invincible. Physical stresses, bends, and external damages can compromise their integrity and performance, hence the need for careful handling and installation.

Coaxial Cable

- Lifespan: Averages between 10-20 years

Coaxial cables have long been the mainstay for transmitting television signals and, in many cases, broadband internet. Characterized by their central conductor, insulating layer, and external shielding, these cables are designed to minimize signal loss and interference. However, their lifespan can be compromised by factors like frequent bending, physical trauma, and issues with the connectors. Regular checks and proper routing can help ensure they remain effective throughout their intended lifespan.

Warning Signs That It’s Time to Replace Your Wiring

Ensuring the safety and functionality of your home’s electrical system is of paramount importance. Over time, wires deteriorate, and the consequences of overlooking this decline can be both costly and dangerous. Recognizing the early warning signs can prevent potential hazards and guarantee uninterrupted electrical service. Below, we delve deeper into these signs, exploring each one’s implications and the underlying issues they might indicate:

- Flickering Lights: If your lights are flickering or dimming intermittently, it could be a sign that the wiring connected to those fixtures is compromised. The problem might be due to a loose connection, overloading, or aged wiring that can’t consistently maintain the required current;

- Persistent Burning Smell: A continuous or recurring burning odor, especially one that’s emanating from outlets or switches, is a serious cause for concern. This often signals overheating or potential short-circuits, which can quickly lead to fires if not addressed promptly;

- Discolored Outlets or Switches: Outlets or switches that appear brown, black, or any shade that’s not their original color can be troubling. Underlying Issue: Discoloration typically results from arcing or excessive heat, suggesting that the electrical components or the wiring connected to them are malfunctioning;

- Regularly Blown Fuses or Tripped Breakers: If your circuit breakers trip frequently or you find yourself constantly replacing fuses, it’s a clear indication of an underlying issue. Constant tripping can be a result of overloading circuits, short circuits, or even ground faults – all of which are symptoms of potentially problematic wiring;

- Frayed or Exposed Wires: Wires that show visible signs of damage, such as fraying, cracking, or exposure, pose immediate risks. Damaged insulation can lead to short circuits, electrical shocks, or fires. Physical wear and tear, poor installation, or even pests like rodents chewing through the insulation can be the culprits.

Tips for Extending the Lifespan of Electrical Wires

The foundation of a safe and efficient electrical system lies not just in quality components, but also in the meticulous care and maintenance of these components over time. Extending the lifespan of your electrical wires is both an economic advantage and a safety imperative. To ensure that your wiring serves you reliably for the longest possible duration, consider the following comprehensive guidelines:

- Prioritize Regular Inspections: Instituting a routine of professional inspections every few years is essential. These inspections delve deep into your electrical system, highlighting wear and tear or potential vulnerabilities. Early identification of issues like wire degradation, insulation breakdown, or emerging safety hazards allows for timely interventions, preventing more significant, costlier problems down the line;

- Be Wary of Overloading: Every circuit and wire is designed to handle a specific electrical load. Consistently pushing them beyond these limits can lead to overheating and wear. By ensuring that your circuits are not overloaded, you can maintain the integrity of the insulation and prevent issues like blown fuses, tripped breakers, and potential fire hazards;

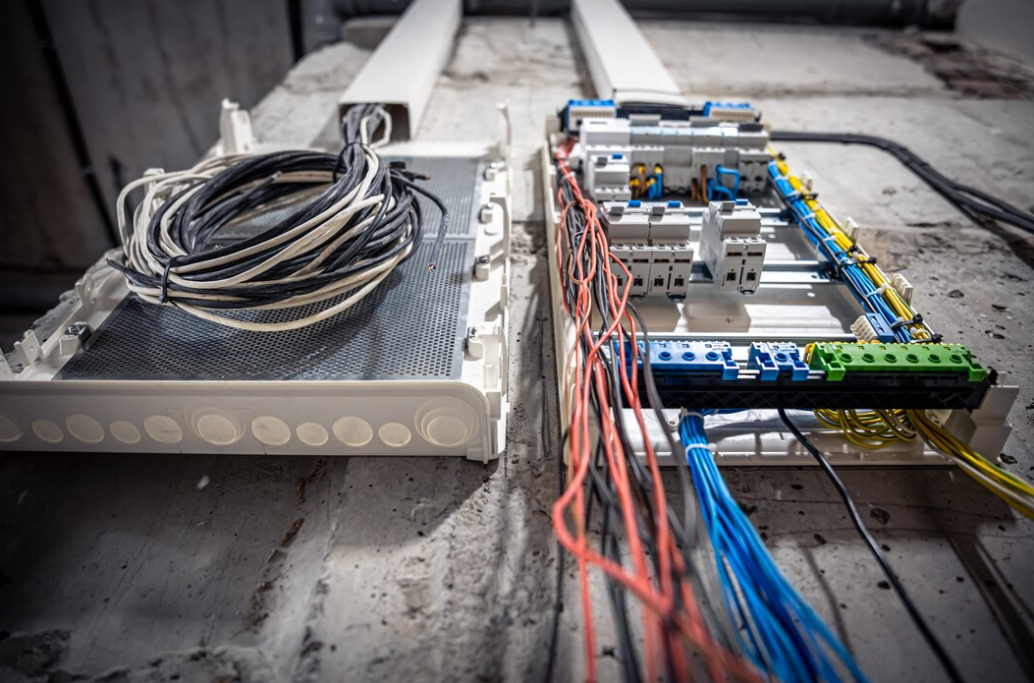

- Opt for Expert Installation and Repairs: The complexities of electrical systems necessitate expertise. Whether you’re looking at a new installation or repairs, always seek out skilled professionals with a proven track record. Expert installations ensure that wires are laid out optimally, minimizing physical stresses, and potential points of failure. Moreover, professionals can provide insights and recommendations tailored to your specific setup and needs;

- Control the Climate Around Your Wiring: The role of environmental factors in the longevity and efficiency of electrical wires is often understated. While wires and electrical components are designed to function within a variety of conditions, they aren’t impervious to the toll that certain climatic elements can take on them. Wires, like any other materials, respond to their environment. High humidity levels or excessively warm temperatures can accelerate the wear of electrical wires and their insulation. Keeping your electrical components in a controlled environment – dry, cool, and away from potential corrosive elements – can drastically enhance their longevity. This not only prevents premature degradation but also optimizes their performance;

- Use Quality Materials and Components: When investing in electrical wires and related components, opt for high-quality materials known for their durability and performance. Premium materials, while sometimes more expensive upfront, often provide better long-term value due to their extended lifespans and reduced maintenance needs.

Conclusion

While the lifespan of electrical wires varies based on material, usage, and environmental factors, regular maintenance and monitoring can help in maximizing their utility. It’s essential to be proactive, ensuring that your electrical system remains safe and efficient for years to come.