In the intricate world of electrical systems, understanding every component’s role is critical for safety and efficiency. One such crucial element is the bus bar, housed within electrical panels and serving as the backbone for power distribution.

In this comprehensive guide, readers will gain insights into its function, types, and essential safety practices, ensuring optimal performance and security.

Table of Contents:

- Insight into Electrical Bus Bars: Functionality and Types;

- The Role and Configurations of Bus Bars;

- Diving Deeper into the Bus Bar’s Structure and Purpose;

- Evolution and Modern-day Applications of Bus Bars;

- Application of Busbars Across Industries;

- Bus Bar Arrangements: Diversity and Application;

- Single Busbar System;

- Double Busbar System;

- Ring Busbar System;

- Comparing Busbars and Cables;

- Conclusion.

Insight into Electrical Bus Bars: Functionality and Types

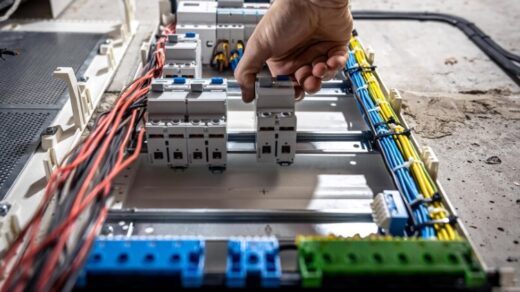

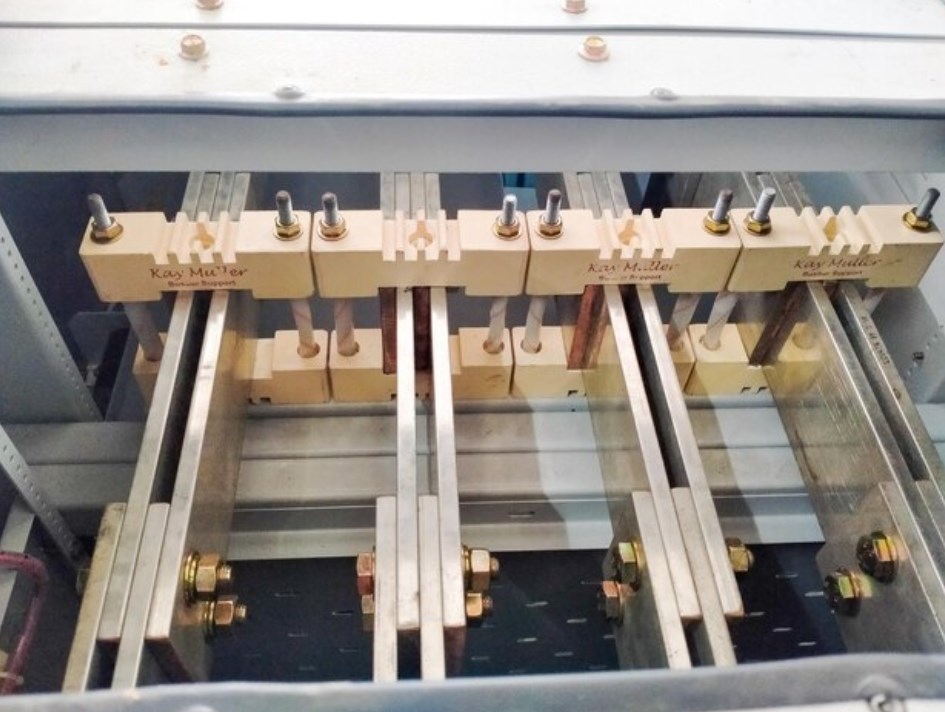

An electrical bus bar is instrumental in simplifying complex power distribution networks, making them more cost-effective and adaptable. Essentially, it is a conductor, typically a metallic strip or bar, securely enclosed within switchgear, panel boards, and busway casings for localized, high-current power distribution. It forms a pivotal junction where electric power is amassed from incoming feeders and is then distributed to outgoing feeders.

Electrical bus bars are characterized by the harmonious operation of multiple lines, which function at identical voltage levels and frequencies. Often, copper or aluminum, known for their excellent conductivity, are the chosen materials for constructing these integral components. Depending on the specific requirements, they are fashioned into pipes or thin-walled tubes to facilitate effective power transmission.

The Role and Configurations of Bus Bars

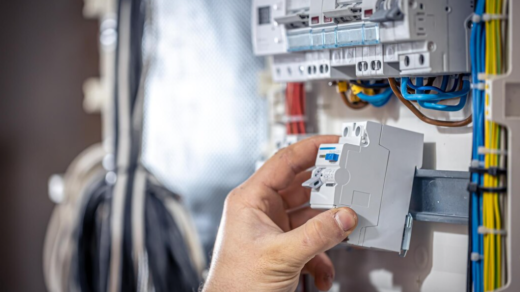

The strategic arrangement of bus bars is pivotal, aimed at ensuring operational flexibility, enhanced reliability, and cost efficiency. These conductive bars are intricately aligned and accompanied by circuit breakers to maximize availability and enhance plant operations. Their design and layout are meticulously planned to offer optimal performance and safety.

Bus bars are not monolithic in design; instead, they are tailored to fit the varying needs of diverse electrical systems. In each of their configurations, a common goal is pursued – the seamless, safe, and efficient distribution of electric power.

Diving Deeper into the Bus Bar’s Structure and Purpose

In the realm of electrical power distribution, bus bars are a quintessential element. With their ability to simplify the complexities of power distribution, these metallic strips or bars are fundamental in the architecture of various electrical systems. Encased within panel boards and switchgear, they work meticulously to ensure power is distributed efficiently and safely.

Bus bars have transcended the conventional norms, adopting sophisticated designs and materials to meet modern electrical systems’ demands. Copper and aluminum variants proliferate, each offering distinct advantages and optimized for specific environments and requirements. Furthermore, these bars can be either insulated or uninsulated, an aspect determined by the overarching needs of the system at hand.

Evolution and Modern-day Applications of Bus Bars

Bus bars have stood the test of time, their inception dating back a century. However, the evolution of electrical systems and the unyielding demand for more efficient energy distribution mechanisms have spotlighted their significance. They have morphed into highly efficient components, with designs ranging from the simplistic to the complex, each catering to the nuanced needs of contemporary electrical infrastructures.

These conductors are not merely about carrying and distributing electrical power. Their role is multifaceted, acting as a hub where electrical power is not just transmitted but is also optimized for efficiency and safety. Every design iteration, material choice, and configuration aims to ensure that power distribution is not just a mechanical process but is attuned to the intrinsic safety and efficiency needs that define modern electrical systems.

Application of Busbars Across Industries

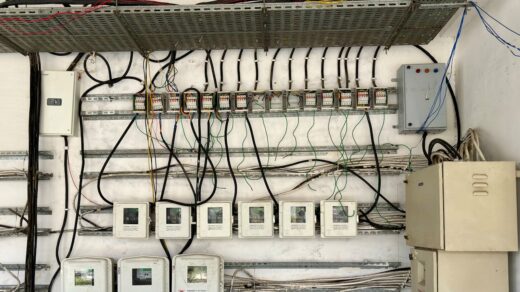

Busbars boast a diverse array of applications, marking their presence wherever the seamless and flexible distribution of power is paramount. From electrical switchyards connecting high voltage equipment to battery banks ensuring low voltage connectivity, these components are intrinsic to the functional blueprint of various sectors including automotive, defense, and technology.

In diverse environments like factories, data centers, and retail facilities, the adaptability of busbars is displayed. The choice between laminated and flexible busbars hinges on the specific operational needs. While laminated versions find their niche in cellular communication systems, power generation systems, and military equipment, flexible alternatives are prominent in electric vehicles, generator connections, and charging stations.

Bus Bar Arrangements: Diversity and Application

Diving deeper, we explore significant busbar arrangements classified according to their structural design. The three pivotal designs include the single busbar system, double busbar system, and ring busbar system.

Single Busbar System

This system, defined by the incorporation of a solitary busbar, connects multiple incoming and outgoing lines. For instance, two 11KV incoming lines, connected via circuit breakers and isolators, feed the outgoing supply lines under this system. The adaptability of the single busbar system can be augmented through sectionalized arrangements.

Pros:

- Ensures partial system functionality during a fault;

- Lower maintenance expenditure.

Cons:

- A fault necessitates a complete system shutdown;

- Expansion activities require total system shutdown.

Double Busbar System

Characterized by the duplication of both low and high-voltage busbars, this system offers enhanced flexibility. An integrated busbar coupling switch facilitates the operational transition between busbars, ensuring uninterrupted functionality during maintenance or repairs.

Pros:

- Enables uninterrupted power supply during busbar faults;

- Feeder circuit breakers can be tested on spare bus bars.

Cons:

- Incurs higher maintenance costs.

Ring Busbar System

With a design where each line is served by two circuit breakers, this system ensures redundancy and uninterrupted service even during a fault in one path.

Pros:

- Redundant paths ensure continuous service;

- Allows circuit breaker maintenance without power interruption.

Cons:

- Integration of additional circuit lines can be complex.

Comparing Busbars and Cables

Busbars, akin to cables, facilitate the transmission of electrical power. However, they stand out for their efficiency, safety, and cost-effectiveness. Their enhanced resistance and superior heat absorption capacity make them ideal for systems that bear high-voltage loads. Additionally, their flexible design allows easy modifications, an aspect where cables lag.

Busbars, encased in robust steel casings, are impervious to damage by rodents—a safety feature cables often lack. Their compact design, coupled with the capacity to handle significant voltage, underscores their efficiency. The ease of installation without the need for extensive structural alterations further adds to their cost-effectiveness.

Conclusion

In sum, busbars have etched their significance in the complex landscape of electrical power distribution. Their structural diversity, ranging from single to double and ring busbar systems, underscores their adaptability, meeting the nuanced demands of various electrical environments. Each design is a testimony to the intricate balance between operational efficiency, safety, and cost-effectiveness.

The comparison between busbars and cables illuminates the former’s superiority, marked by enhanced resistance, safety features, and cost-saving attributes. Whether in the steel encasing that wards off potential damage or the compact design that optimizes space, busbars epitomize efficiency.

As we navigate an era where the demands on electrical systems are escalating, the role of busbars is not just pivotal but also evolving. They are not static components but are dynamic elements, adapting and morphing to meet the contemporary and future demands of power distribution. Each type, from laminated to flexible, is a solution engineered with precision, ensuring that whether in a factory, data center or a sophisticated defense setup, power is not just transmitted but is managed with unwavering efficiency and safety.

In closing, busbars are not mere conductors; they are the silent sentinels and efficient managers of electrical power, ensuring that every watt transmitted is a step towards a future where efficiency, safety, and cost-effectiveness define our interaction with electrical power. Their evolution, marked by technological innovations and enhanced designs, is a journey towards optimized electrical power management, where every component, connection, and transmission is a stride toward unparalleled operational excellence.